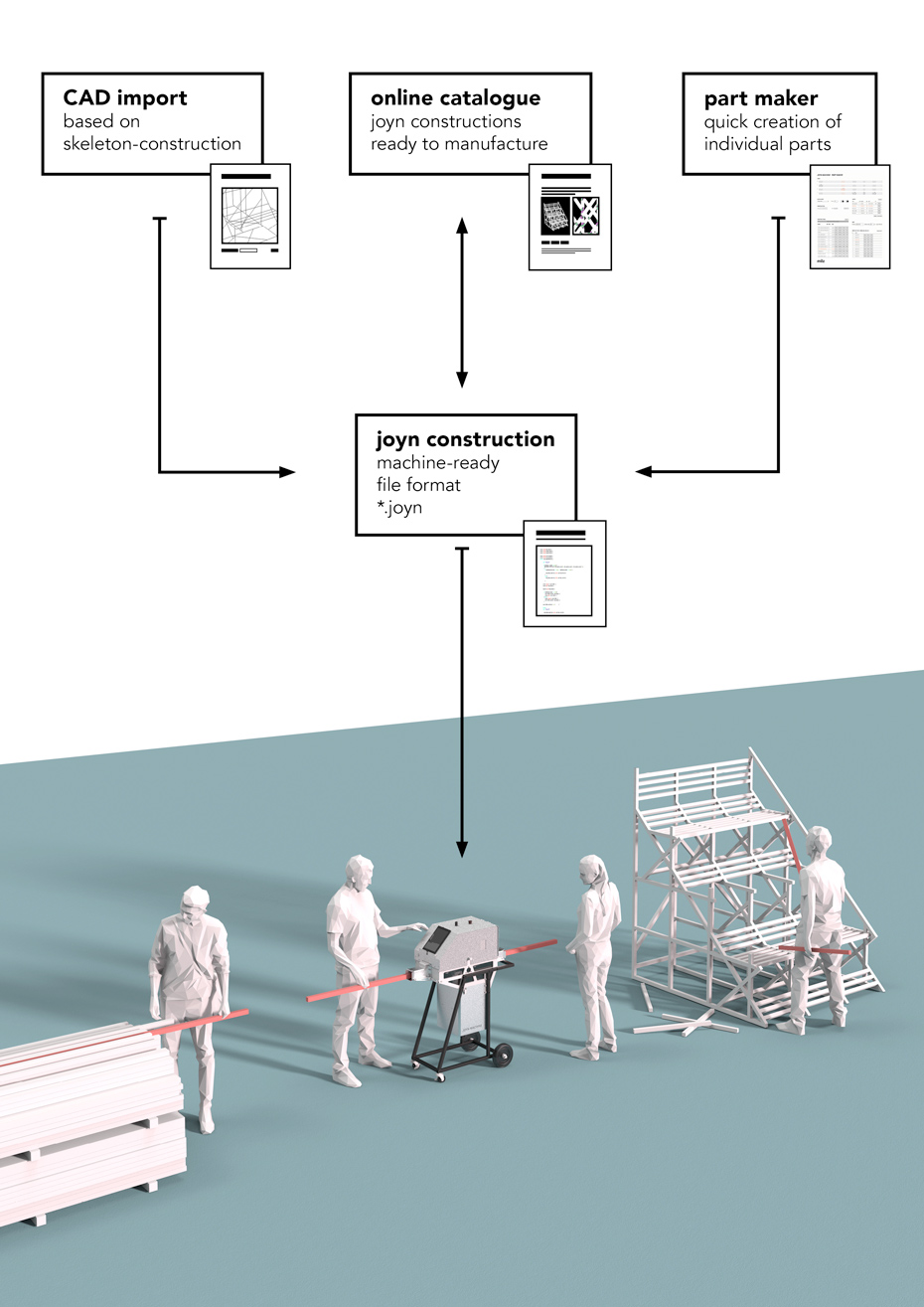

JOYN MACHINE is following an “all-in-one concept” covering the entire production chain from designing a wooden structure, to processing the raw material (wooden slats), to manufacturing the wooden parts that can then be assembled into the designed structure.

The idea of providing one tool that combines all these skills is achieved by closely linking software and hardware components, but also by the construction of the hardware itself: With a weight of about 100 kg, JOYN MACHINE is portable. At the core, it is a three-axis milling machine with a rolling conveyor for the y-axis positioning the wooden slats, including mechatronic, automatic calibration. In practice this means that the user will take a wooden slat and “feed” it to the machine which then does all the rest.

The milling-engine has a power-output of 1 kw and can use milling-tools with an operating width from 6 to 12 mm. The machine is completely cased-in to protect the user from noise and it has a built-in solution for the extraction of waste using an external heavy-duty vacuum cleaner.

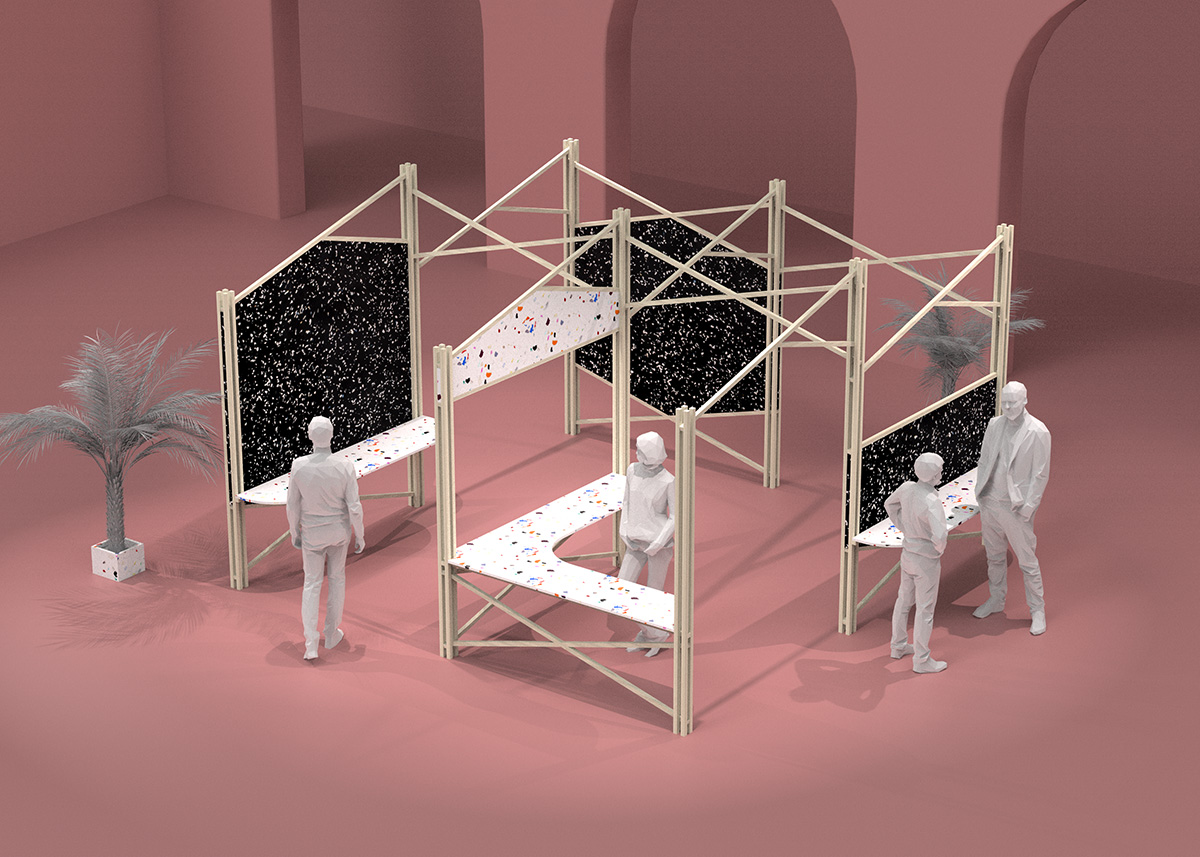

The machine uses a bespoke motion controller circuit board and generally features fully integrated electronics. On the software side, the focus is clearly on user-centricity and “app-like” interaction and the possibility to control the machine via a built-in tablet computer - including live video of the milling process from the inside of the the machine.

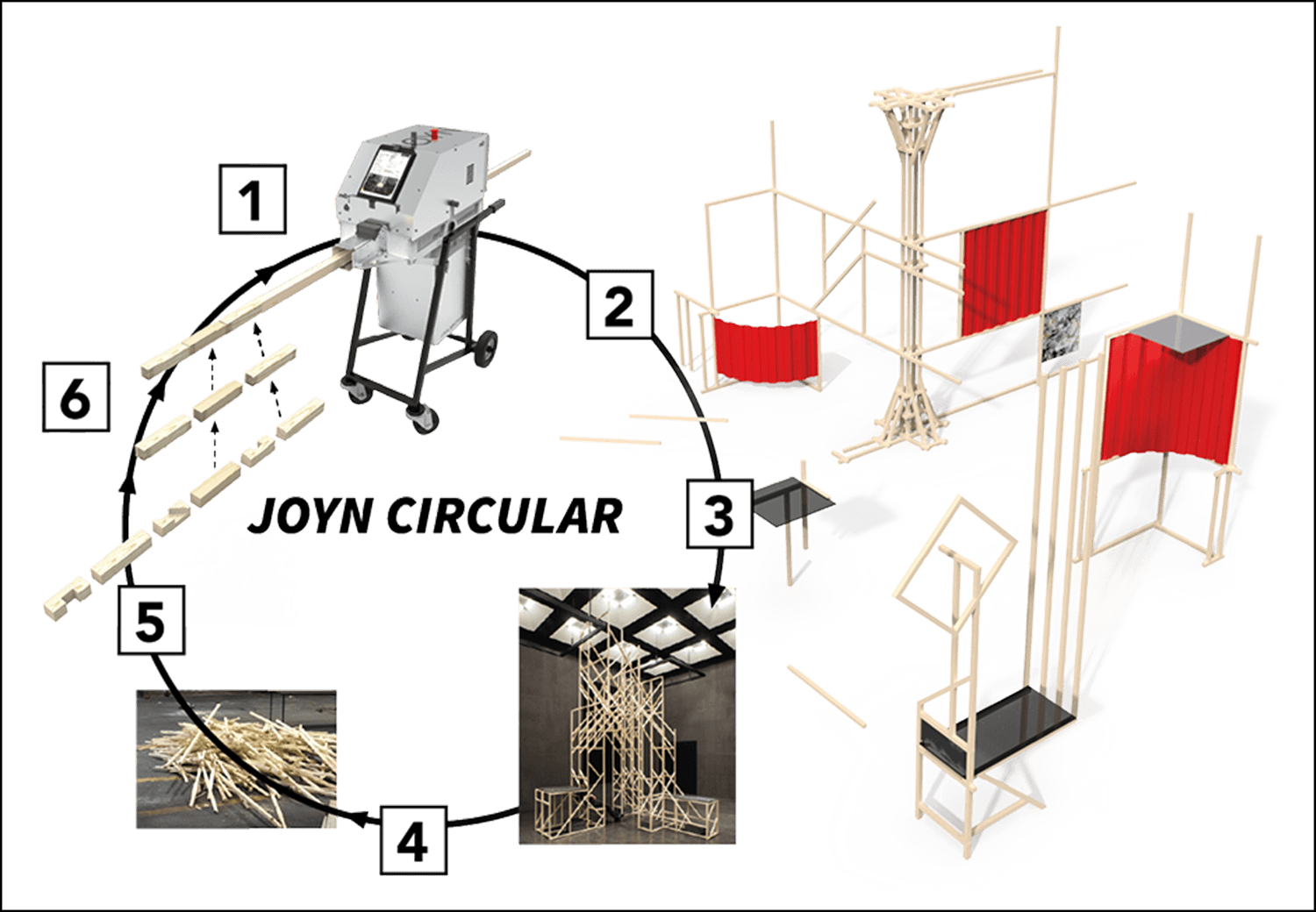

JOYN CIRCULAR

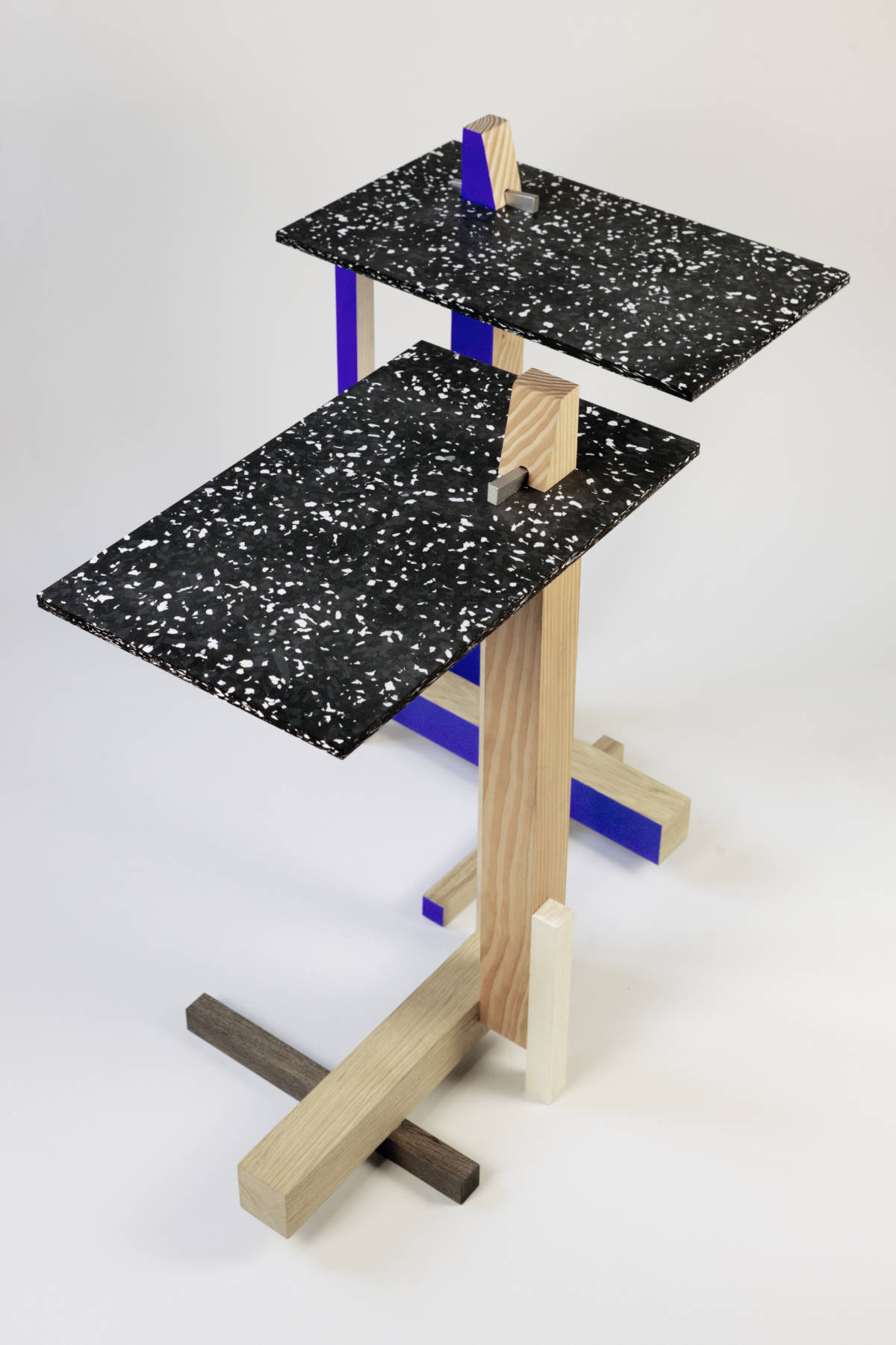

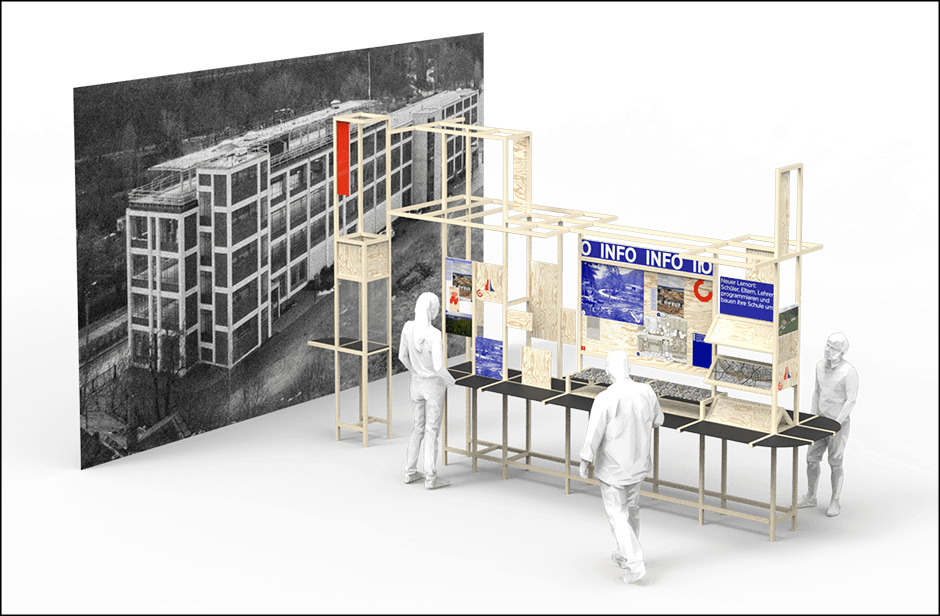

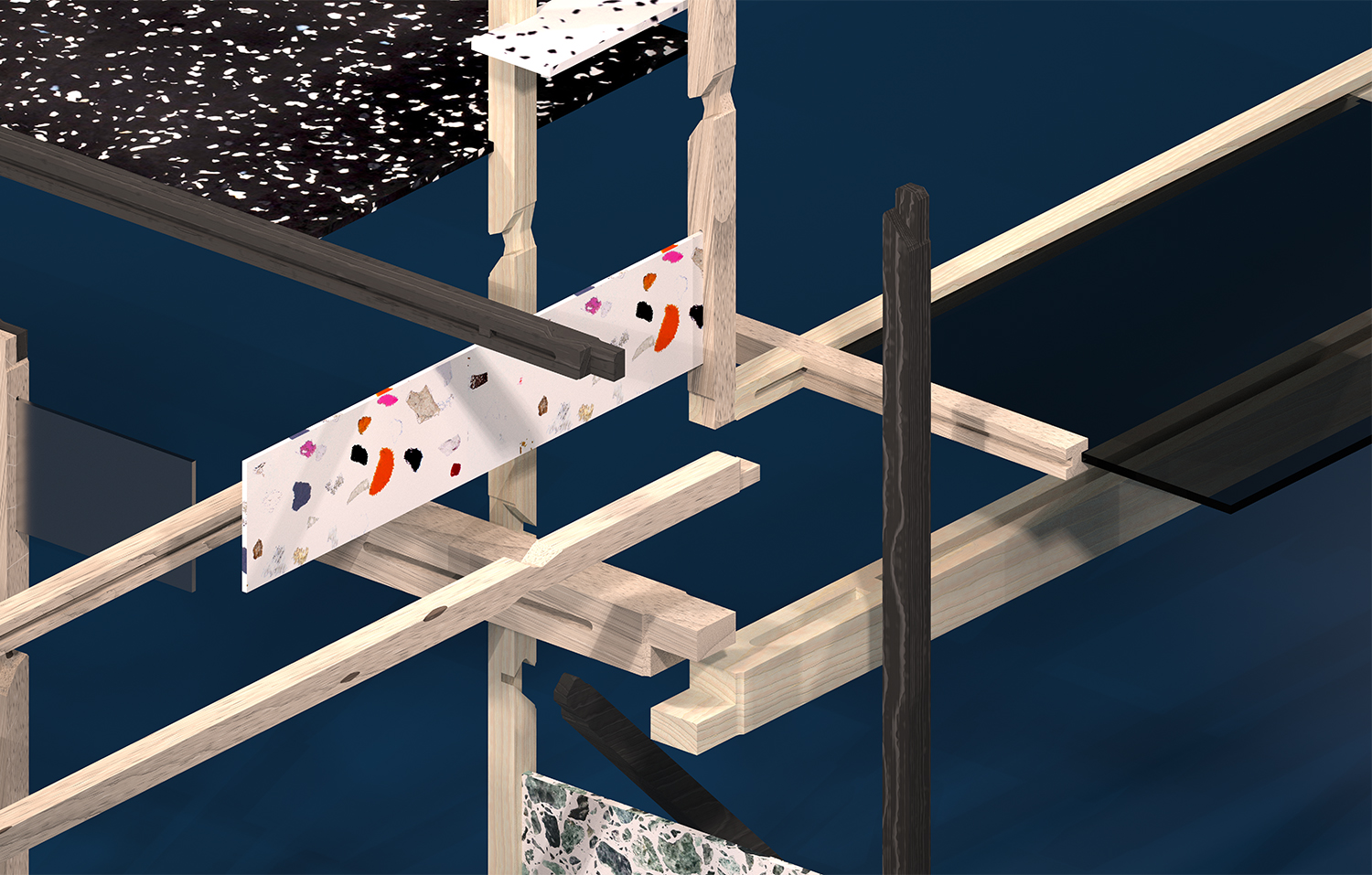

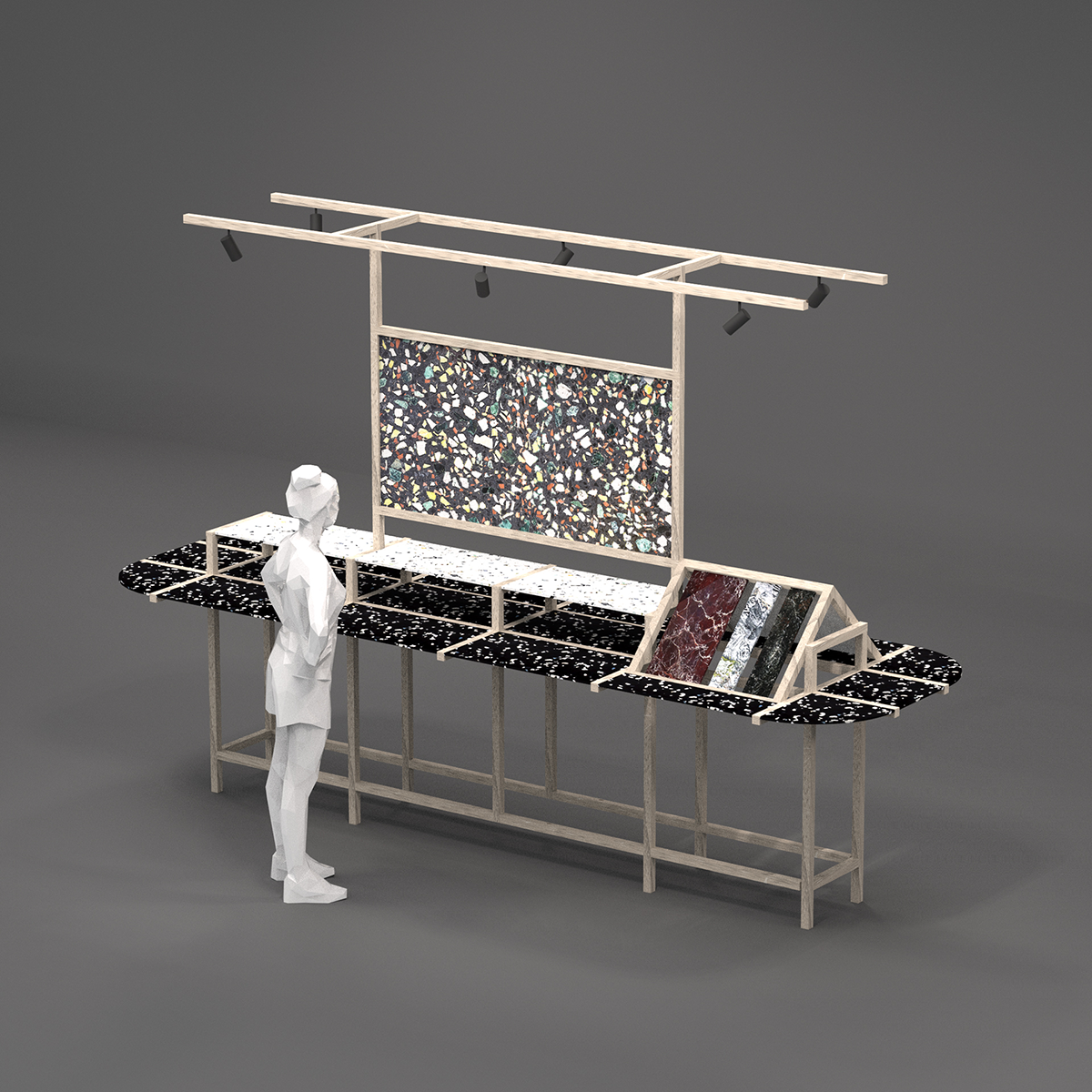

After dismantling, the circular process feeds the construction back into a new production cycle by studio milz. Furthermore, the exhibition architecture can be easily disassembled due to glue-free wood connections and enables damage-free disassembly and the recovery of all used materials.

1. Design and Production / 2. Assembly of milled wooden kits / 3. Final construction / 4. Deconstruction of outdated projects / 5. Return to the recycling cycle / 6a Extraction of undamaged slat pieces / 6.b glued finger-jointing / 6c manufacturing of solid structural timber (Konstruktionsvollholz KVH)